Recently, Professor Li Li’s team from the School of Metallurgy, NEU has made important progress in the research of bifunctional catalyst materials. The relevant research achievements were published on the top international journal, Journal of the American Chemical Society (JACS), with “Superstructure Assisted Single-Atom Catalysis on Tungsten Carbides for Bifunctional Oxygen Reactions” as the topic. School of Metallurgy, NEU is the first completion unit, Hongguan Li, a doctoral student of the School of Metallurgy, is the first author, and Professor Li Li is the communication author.

The team proposed a catalyst with superlattice and single atom dispersed on tungsten carbide substrate at the same time, and observed the formation of Co superlattice at the edge of WxC by iDPC technology. Through the compressive stress of Co superlattice on WxC, the d band of Co monoatomic site was optimized, the desorption of intermediates was promoted, the overpotential of ORR/OER was reduced, and the reaction kinetics was accelerated.

Monoatomic catalysts are considered to be an important way to develop high-performance and bifunctional electrocatalysts because of their high metal utilization rate and maximum active sites. The adjustable electronic structure provides an ideal platform for the design of efficient electrocatalysts. At present, most of bifunctional SACs reported are based on M-N-C structure, and atomic metal (M) is dispersed on nitrogen-doped carbon (N-C) substrate. However, the interaction between N and metal is very likely to form aggregates, which greatly limits the loading of metal atoms, thus reducing the number of effective active sites of ORR/OER. Tungsten carbide substrate was explored due to its advantages including excellent chemical resistance, high conductivity, platinum-like electronic properties and no active center with strong heteroatom coordination. These advantages are prerequisites for designing efficient and durable bifunctional electrocatalysts. Owning to the existence of dispersed Co single atoms and the Co superlattice at the edge interface combining with the advantages of atomic catalysis and superstructure catalysis, the utilization rate of metals was maximized, thus improving the surface catalytic activity. This research provided a new insight into atomic catalysts and opened up a new way for designing advanced materials for electrocatalysis and energy storage system. Analysis and Testing Center of the NEU provides an important support for data collection and characterization.

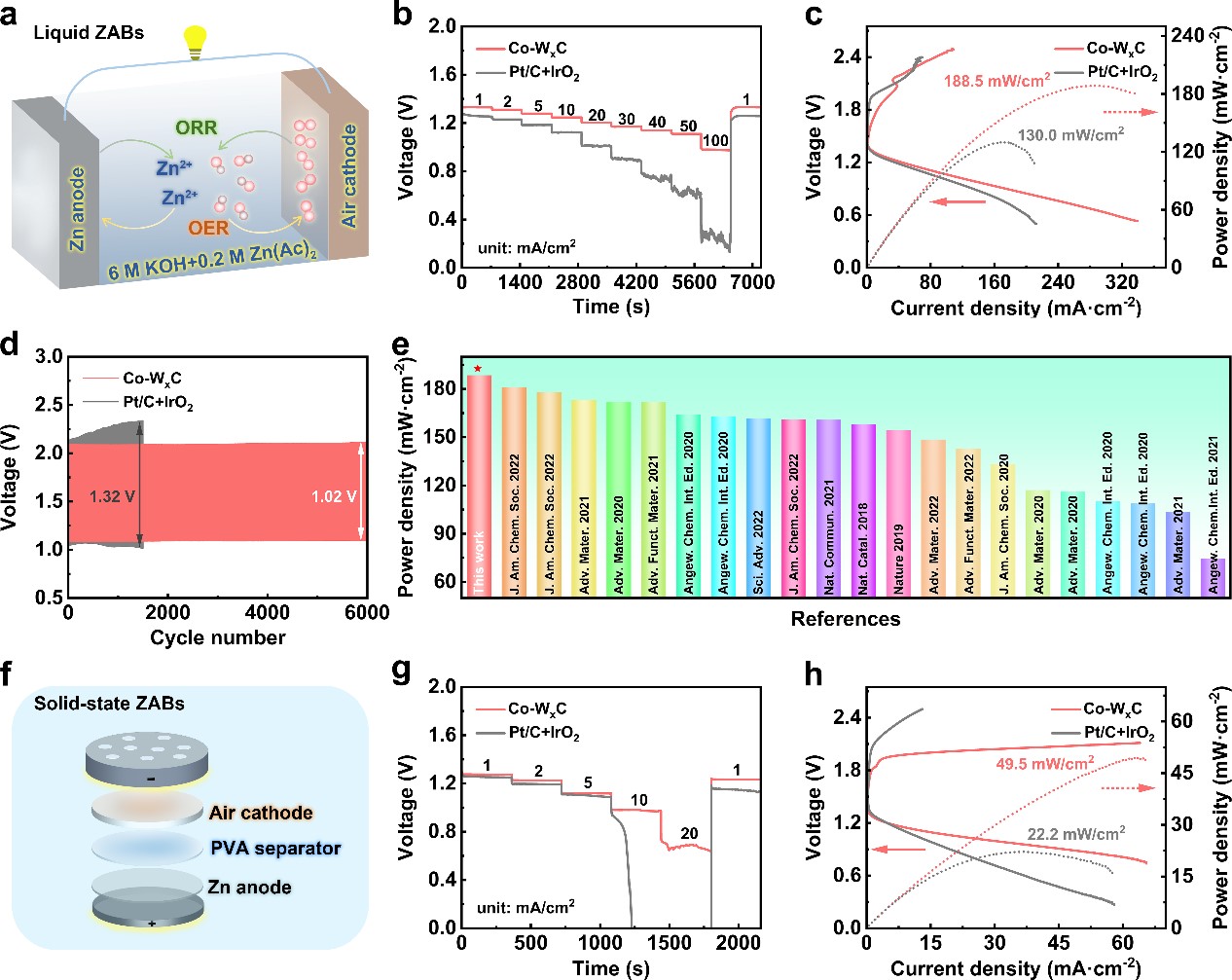

Fig. 1 Schematic diagram of performance of electrocatalytic device